About Metal Leaf

TOP

About Metal Leaf

About Metal Leaf

Metal leaf – soft, ultrathin metal

Metal leaf refers to extremely thinly-beaten metals such as gold, silver, platinum and copper, of which gold leaf is the most popular.

Gold leaf’s gloss offers not only luxury and beauty but also sublimity and comfort.

In the religious field, gold leaf has been valued as a source of eternal light and used for temples and shrines as well as Buddhist images, altars and ritual items.

It is also used for various other purposes such as folding screens, paper door decorations, lacquerware, ceramics and textiles and recently in a wide range of areas including interior design, architecture, food and esthetics.

In the religious field, gold leaf has been valued as a source of eternal light and used for temples and shrines as well as Buddhist images, altars and ritual items.

It is also used for various other purposes such as folding screens, paper door decorations, lacquerware, ceramics and textiles and recently in a wide range of areas including interior design, architecture, food and esthetics.

Gold leaf, with a thickness of 0.1 micron, has a distinctive attractiveness and possibilities that are different from those of metal itself, such as flexibility, softness and beauty.

Metal leaf is a one-of-a-kind item with a hidden attractiveness beyond verbal expression.

Metal leaf is a one-of-a-kind item with a hidden attractiveness beyond verbal expression.

The history of Kanazawa metal leaf

Kanazawa – The metal leaf city that produces almost all of Japan’s metal leaf

Kanazawa gold leaf has a long history, although the exact year that production commenced is unclear. There is a historical document indicating that gold and silver leaf production was ordered by Maeda Toshiie, the first lord of Kaga Domain in 1593.

At the end of the 17th century, the government established Hakuza in Edo (present-day Tokyo) to control the manufacturing and sales of metal leaf, and prohibited gold leaf production except for in Hakuza in Edo and Kyoto. Nevertheless, metal leaf workers in Kanazawa continued their efforts to preserve gold leaf production.

Subsequently, the control of metal leaf production ended when the Edo government collapsed due to the Meiji restoration. As a result, metal leaf production disappeared from Edo, while Kanazawa became free to produce metal leaf, becoming famous for its gold leaf production.

At the end of the 17th century, the government established Hakuza in Edo (present-day Tokyo) to control the manufacturing and sales of metal leaf, and prohibited gold leaf production except for in Hakuza in Edo and Kyoto. Nevertheless, metal leaf workers in Kanazawa continued their efforts to preserve gold leaf production.

Subsequently, the control of metal leaf production ended when the Edo government collapsed due to the Meiji restoration. As a result, metal leaf production disappeared from Edo, while Kanazawa became free to produce metal leaf, becoming famous for its gold leaf production.

The cultural promotion policy of the Maeda Family of Kaga Domain

The Maeda Family had protected their domain from the government through generations by placing importance on cultural promotion instead of martial training. They therefore promoted various traditional craft techniques. As a result, a number of crafts flourished, creating the brilliant Kaga Hyakumangoku culture, and Kanazawa is now referred to as a “crafts kingdom”. It is known that this city had an abundant need for gold leaf as a craft material.

A climate suitable for metal leaf manufacturing

Kanazawa possesses water and climate suitable for metal leaf manufacturing. The city’s soft water and moist climate are suited to making the paper used for beating metal leaf, which requires subtle adjustment of the paper’s moisture.

Perfected metal leaf manufacturing techniques

During the period in which metal leaf production was controlled by the government, workers continued to manufacture metal leaf in secret using materials that were insufficient in quality and quantity. They worked through trial and error, using their experience and ingenuity, resulting in the nurturing of excellent metal leaf manufacturing techniques in Kanazawa.

Due to these natural and historic factors, Kanazawa has become a city well-known for its metal leaf production, and manufactures most of Japan’s metal leaf.

Due to these natural and historic factors, Kanazawa has become a city well-known for its metal leaf production, and manufactures most of Japan’s metal leaf.

Gold leaf manufacturing methods

There are two production methods for gold leaf: entsuke, a traditional production method, which has a history of over 400 years, and tachikiri, a modern production method, which began around 1970. In gold leaf manufacturing, pieces of gold alloy are inserted between sheets of paper and beaten. The greatest difference between these two methods is the gold beating paper.

Entsuke gold leaf (produced by the traditional method)

A 400-year-old traditional method indispensable for the repair of national treasures, and also regarded as a cultural asset

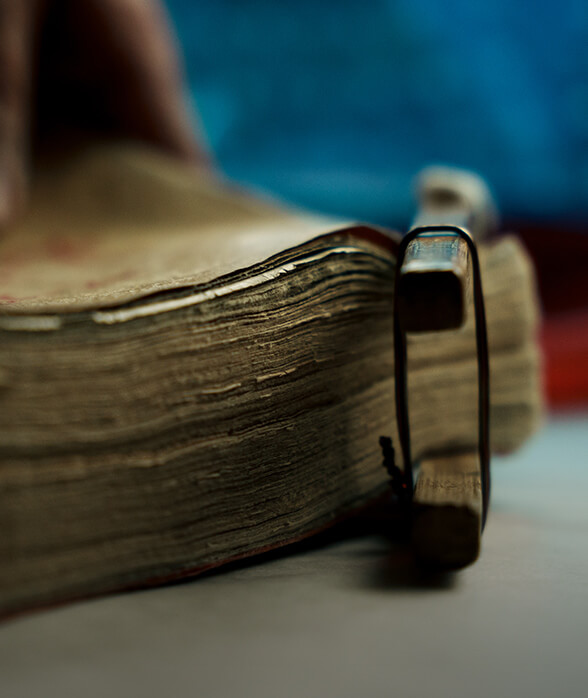

The entsuke gold leaf manufacturing method is a traditional technique with a history of over 400 years. Although gold leaf is now beaten by a machine instead of by hand, traditional handmade Japanese paper is still used for beating here in Kanazawa.

In order to create gold beating paper, traditional handmade Japanese paper made from ganpi plant fibers is carefully processed with water, straw ash lye, persimmon tannin and egg white for as long as half a year.

The entsuke gold leaf manufacturing method was selected as a Japanese traditional technique to be preserved by the Agency for Cultural Affairs on October 23, 2014.

In addition, it was registered as a UNESCO Intangible Cultural Heritage under “traditional skills, techniques and knowledge for the conservation and transmission of wooden architecture in Japan”, which consist of 17 fields.

About UNESCO Intangible Cultural Heritage

In order to create gold beating paper, traditional handmade Japanese paper made from ganpi plant fibers is carefully processed with water, straw ash lye, persimmon tannin and egg white for as long as half a year.

The entsuke gold leaf manufacturing method was selected as a Japanese traditional technique to be preserved by the Agency for Cultural Affairs on October 23, 2014.

In addition, it was registered as a UNESCO Intangible Cultural Heritage under “traditional skills, techniques and knowledge for the conservation and transmission of wooden architecture in Japan”, which consist of 17 fields.

Tachikiri gold leaf (produced using the modern method)

The main technique in use today, developed to improve productivity

The tachikiri gold leaf manufacturing method was developed around 1970 to improve productivity. Tachikiri gold leaf is also referred to as modern gold leaf. It is the main technique used in recent years due to its high production efficiency.

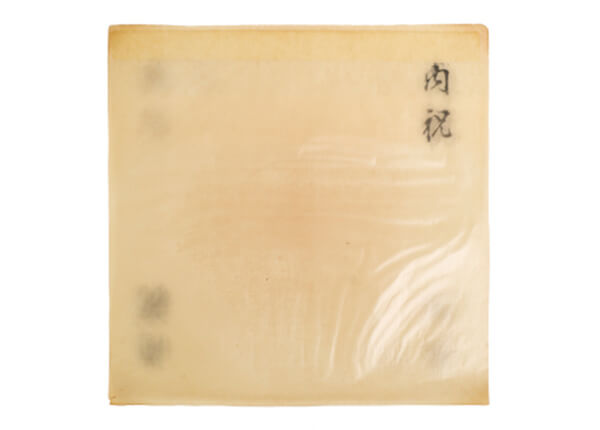

This method uses glassine paper with special carbon applied. Tachikiri gold leaf can be manufactured in less time than entsuke gold leaf, which requires a great deal of attention and time for paper preparation and gold leaf beating.

Also, in the entsuke gold leaf trimming process, each sheet is placed on leather and trimmed using a bamboo frame, while in the tachikiri gold leaf trimming process, 500 to 1000 sheets of gold leaf are layered alternately between sheets of Japanese paper and trimmed at once.

This method uses glassine paper with special carbon applied. Tachikiri gold leaf can be manufactured in less time than entsuke gold leaf, which requires a great deal of attention and time for paper preparation and gold leaf beating.

Also, in the entsuke gold leaf trimming process, each sheet is placed on leather and trimmed using a bamboo frame, while in the tachikiri gold leaf trimming process, 500 to 1000 sheets of gold leaf are layered alternately between sheets of Japanese paper and trimmed at once.

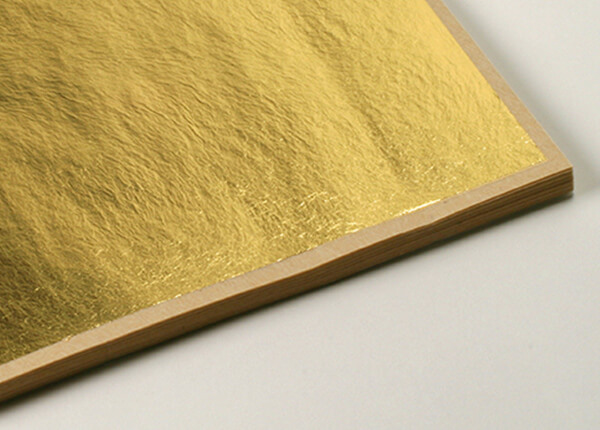

Entsuke gold leaf

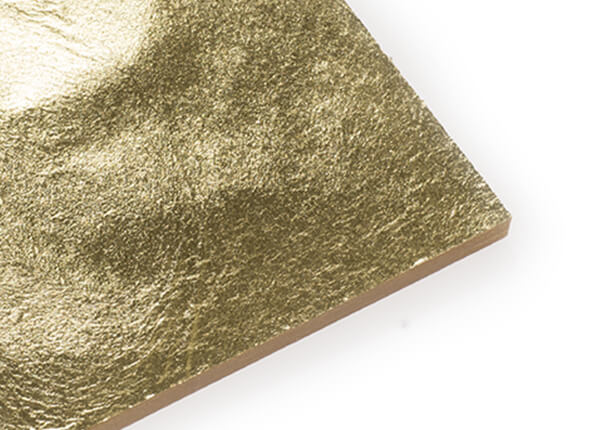

Tachikiri gold leaf

Gold beating paper

Handmade ganpi paper is carefully processed with water, straw ash lye, persimmon tannin and egg white for as long as half a year.

Glassine paper applied with special carbon

Trimming

Each sheet is placed on leather and trimmed using a bamboo frame.

Sheets of gold leaf are layered alternately between sheets of Japanese paper and trimmed at once.

Finish

The paper is larger than the gold leaf, creating a margin, which is the origin of the name entsuke (with a margin).

The paper and gold leaf are the same size, since they are cut together.

*Although there are modern gold leaf production methods similar to the tachikiri method in other countries, the method using handmade ganpi paper for beating gold (entsuke method) is unique to Japan.

*The alloy composition is the same in both entsuke gold leaf and tachikiri gold leaf, despite the difference in their production methods.